BABA SPINNERS LIMITED

A Testament to Uncompromising Quality

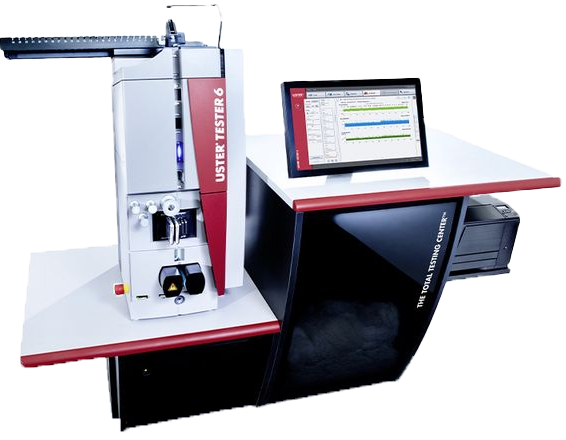

At BABA SPINNERS LIMITED, quality transcends mere principle; it is the creed by which we operate. Our steadfast commitment to excellence ensures that every yarn spun is a reflection of our dedication. We take immense pride in sourcing only the finest cotton, subjecting it to rigorous testing to guarantee unparalleled quality and purity. Each lot of cotton is meticulously examined, ensuring that only the highest-grade fibers enter our production line. Through a series of meticulous steps, we eliminate impurities, affirming that our yarns and fabrics meet the loftiest standards of quality and purity.